Related Knowledge About FFCs

Blaze Display Technology Co., Ltd. | Updated: Nov 27, 2018

FFCs: Flat Flexible Cables

Flat Flexible Cables (FFCs) are a type of flexible cable that provide a 1:1 connection between devices. They consist of multiple flat wires placed parallel to each other and covered with a protective shielding tape. This makes these cables a great option for projects that require quick connections or high-flex applications where the cable needs to bend repeatedly without breaking.

Types of FFCs:

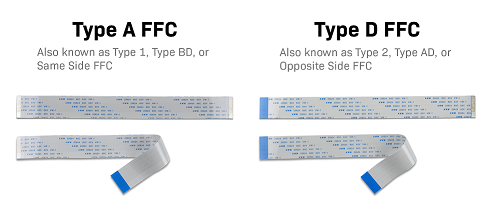

There are two main types of FFCs, each of which has a different layout of contacts, or pins. Both types can be referred to by a variety of names, but they’re most commonly known as Type A and Type D.

l Type A (also known as Type 1, Type BD, or Same Side): Each end of the cable is lined with a row of pins, both of which lie on the same side of the FFC’s surface. This is the most commonly used type of FFC.

l Type D (also known as Type 2, Type AD, or Opposite Side): Each end of the cable is lined with a row of pins, one of which lies on the top side of the FFC and the other on the bottom side. This type of FFC is less common and is typically used in special-case applications, for example, to connect a device that has a standard pin layout to a device that has a reverse-order pin layout.

Parts of an FFC:

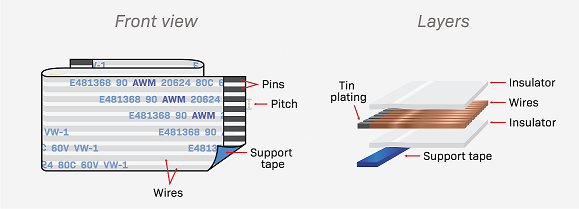

l Wires: Flat conductive paths that carry electrical signals between the devices that the FFC is connected to.

l Pins: Individual conductive contact points at each end of an FPC that connect to corresponding pins on another device.

l Pitch: The distance between the centers of two adjacent pins. The pitch size determines the cable's compatibility with connectors.

l Support tape: Reinforcing layers added to ends of the FFC to make it easier to insert into a connector without damage.

What FFCs are Made of

FFCs are made of a row of flat wires composed of copper and plated in tin at each end. A flexible polyester material is covered around the row of wires to insulate and protect the conductors. At each end of the cable are rectangular stiffeners, which are typically made of a thicker polyester material.

How FFCs Work

FFCs are designed to connect to a device at each end through a 1:1 connection, meaning that each pin on one end of the FFC corresponds exactly to the same number pin on the device it’s being connected to. Once an FFC is properly connected to a device at each end, electrical signals are able to travel from one device through the conductors of the FFC to reach the other device. This connection allows the two devices to communicate while they’re connected with the FFC and a power source.

Advantages of FFCs:

l High flexibility: The flexible materials that FFCs are composed of make them suitable for applications requiring frequent movement.

l Quick setup: The simple process behind setting up an FFC between devices allows for quick connecting and disconnecting.

l High versatility: The function of an FFC is to create a 1:1 connection between devices, which means the cable can easily be reused in any other projects that require a 1:1 connection.

l Cost-effective: FFCs generally cost less to produce than FPCs, so they can be bought at a lower cost.

Disadvantages of FFCs:

l Limited complexity: FFCs cannot support the same level of circuit complexity as FPCs, so they are not well suited for advanced functionality requirements.

l Durability: FFCs may be less durable than FPCs in harsh environments.

Common Uses of FFCs:

l Cameras: In cameras, FFCs connect the image sensor with the processing board to transmit high-resolution image data.

l Robotics: FFCs are often used in moving robotic parts like robotic arms, making up flexible joints and allowing for a wide range of motion.

l Consumer electronics: FFCs are used to connect components within everyday devices such as laptops, printers, and monitors.

l Automotive: Dashboards, infotainment systems, and other in-car electronics use FFCs to make simple connections within the system.

l Medical devices: FFCs are incorporated into imaging equipment and diagnostic machines used within medical spaces.

l Industrial equipment: Industrial robotics and automation systems utilize FFCs to connect many components throughout the machinery.

l Home appliances: FFCs are utilized across household appliances like washing machines, microwaves, and other household devices.

- Next:LED Backlit