How to Select LCD Modules for Extreme Temperatures

Blaze Display Technology Co., Ltd. | Updated: Nov 27, 2018

Industrial, non-automotive transportation and military sectors, among others, often require LCD character or graphics displays that can operate in extreme temperature environments. Typically, standard LCD character and graphics modules provide a temperature range of 0°C to +50°C. However, several display manufacturers offer extreme temperature models with operating temperatures of -40°C to +80 or +85°C. There also is a wide selection of standard versions that range from -20°C to +70°C.

While the operating temperature range specification is clearly one of the most important characteristics of the display for extreme hot/cold environments, engineers also need to keep several other factors in mind when selecting a display for these applications. Some of these factors include visual display requirements, power consumption, and, of course, cost.

One of the first things that designers need to consider is the end use. The application is going to dictate the type of display required — what are the environmental conditions; what type of information will be displayed — characters (numbers or letters) or graphics — is power consumption a factor, and what performance trade-offs can be considered versus cost.

The operating environment of the LCD display — UV exposure, moisture, humidity, temperature — all of these factors are important when designing an extreme temperature display into an application.

Other factors to consider include LCD technology, display formats, and backlighting options. LCD character and graphics modules are available in several technologies, including twisted nematic (TN), super-twisted nematic (STN), and film-compensated super-twisted nematic (FSTN), which all have an impact on the color and contrast of the displays as well as cost. For example, FSTN provides the highest contrast and widest viewing angle, but it costs more than the other two options. Although the contrast is the least sharp for the TN option, it offers a faster response time and is the lowest-cost option.

If a customer decides to use a segmented-type display with a quarter-duty cycle, then TN is okay to use. If the duty cycle is one-sixteenth and higher then we recommend using either STN or FSTN type. STN/FSTN both offer higher contrast ratio and better view angle than TN fluid at higher duty-cycle rates.

Designers also have a choice of display formats — reflective (requires no backlighting), transflective (can be used with or without backlighting), and transmissive (requires a backlight) — and type of backlighting (LED, EL or CFL). Each of the backlighting options has its own set of advantages/disadvantages. For example, EL backlighting enables a very thin LCD module but offers limited sizes. On the other hand, LED backlighting offers a higher brightness and easier brightness adjustment but can produce cold or hot spots.

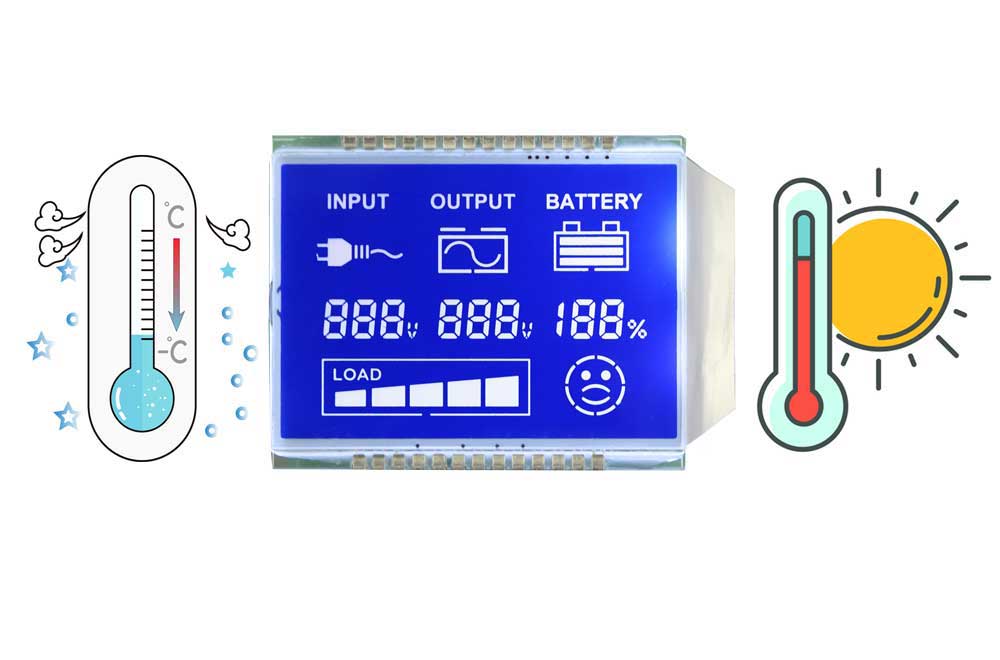

Depending upon what the user wants to display on the screen, if it’s numerals and icons, then go with an LCD segmented-type display. If the user wants to display characters and graphics, then we offer high-duty displays that can go from one-sixteenth to one-two-hundred and fortieth duty without compromising the performance of the display at extreme temperatures of -40°C to +85°C.

If the display will be used during both daytime and nighttime applications, go with transflective mode. If the display will only be used during the nighttime, go with transmissive mode and if the display will only be used during daytime, go with reflective mode, which does not require a backlight.

Displays also are available in positive (dark characters on light background) or negative (light characters on a dark background) modes. Typically, a wide range of colors are available.